Which of the Following Are Related to Lean Production

Link operations through a push system. Link operations through a push system.

The Complete Lean Manufacturing Guide Tulip

A philosophy of waste elimination.

. Never running out of inventory. Attack strategies are. The is the defect level for which lots are regarded as bad lots.

Waste is anything that does not add value to the product. 1 Specify value - identify the value of a product form the customers perspective. Thus it can be concluded that lean production is a philosophy of eliminating the waste from a process typically from the manufacturing process.

Lean production may be one of the best tools for implementing green strategies in manufacturing and service processes. When implementing a lean production system a stabilized schedule is achieved using which of. Lean production is driven by the pull system of the customers order.

Managers being held responsible for quality of the work turned out E. In designing a lean production facility layout a designer should do which of the following. Always keep operations on a single floor of the factory.

Core idea do more with less. Lean production demands high levels of quality at each stage of the process strong vendor relations and a fairly predictable demand for the end product. A philosophy of waste elimination B.

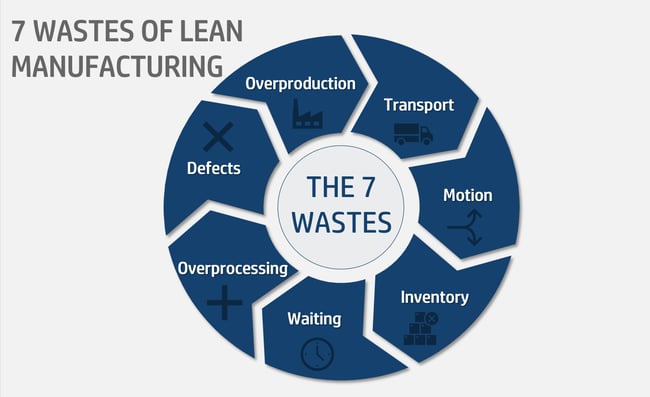

Creating a Lean Production System. A- steps that create value b- steps that. 1- overproduction 2- waiting time 3- material movement 4- inventory 5- overprocessing 6- worker movement 7- defective products.

Lean production means supplying the customer with exactly what the customer wants when the customer wants it without waste through continual improvement. A philosophy of waste elimination B. Locate flexible workstations off line.

Design for work flow balance. Which of the following are assignable cause. In a lean production system we expect to see which of the following.

Henry Ford used JIT concepts as he streamlined his moving assembly lines to. Full use of capacity. Locate flexible workstations off line.

Design for work flow balance. 1 MGMT6355 FINAL EXAM two hours Student name. The following is not a major contributor in the development of Control Charts and Sampling plan.

Lean production is typically associated with which of the following companys production systems. A PHILOSOPHY OF WASTE ELIMINATION. What are the advantages of templates over diagrams.

Waste elimination is the related term to lean production from the given options. 2 Identify the value stream - usually 3 types of actions. No extra inventory B.

Lean production is a management philosophy and a pull system throughout the plant. Never running out of inventory D. Proctor and Gamble b.

Organizational models are. More parts and fewer standardized product configurations D. Lean production is an integrated set of activities designed to achieve high-volume production using minimal inventories of raw materials work in process and finished goods.

Improved small group functioning. Balance capacity using job shop analysis. Extra inventory of critical parts held just-in-case C.

Which of the following is related to lean production. Design for work flow balance. In the textbook Toyotas Fujio Cho identified which of the following types of waste to be eliminated.

Balance capacity using job shop analysis. Section 1 Multiple-choice questions 2 points for each total23570 points 1Which of the following is related to lean production.

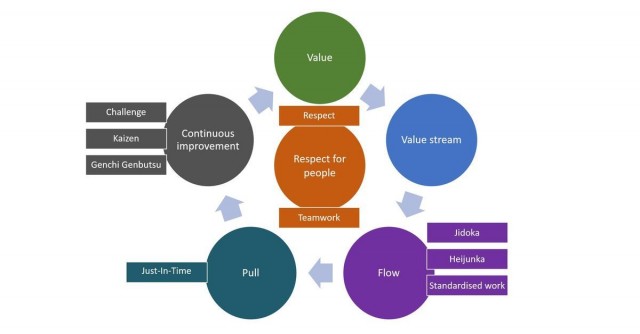

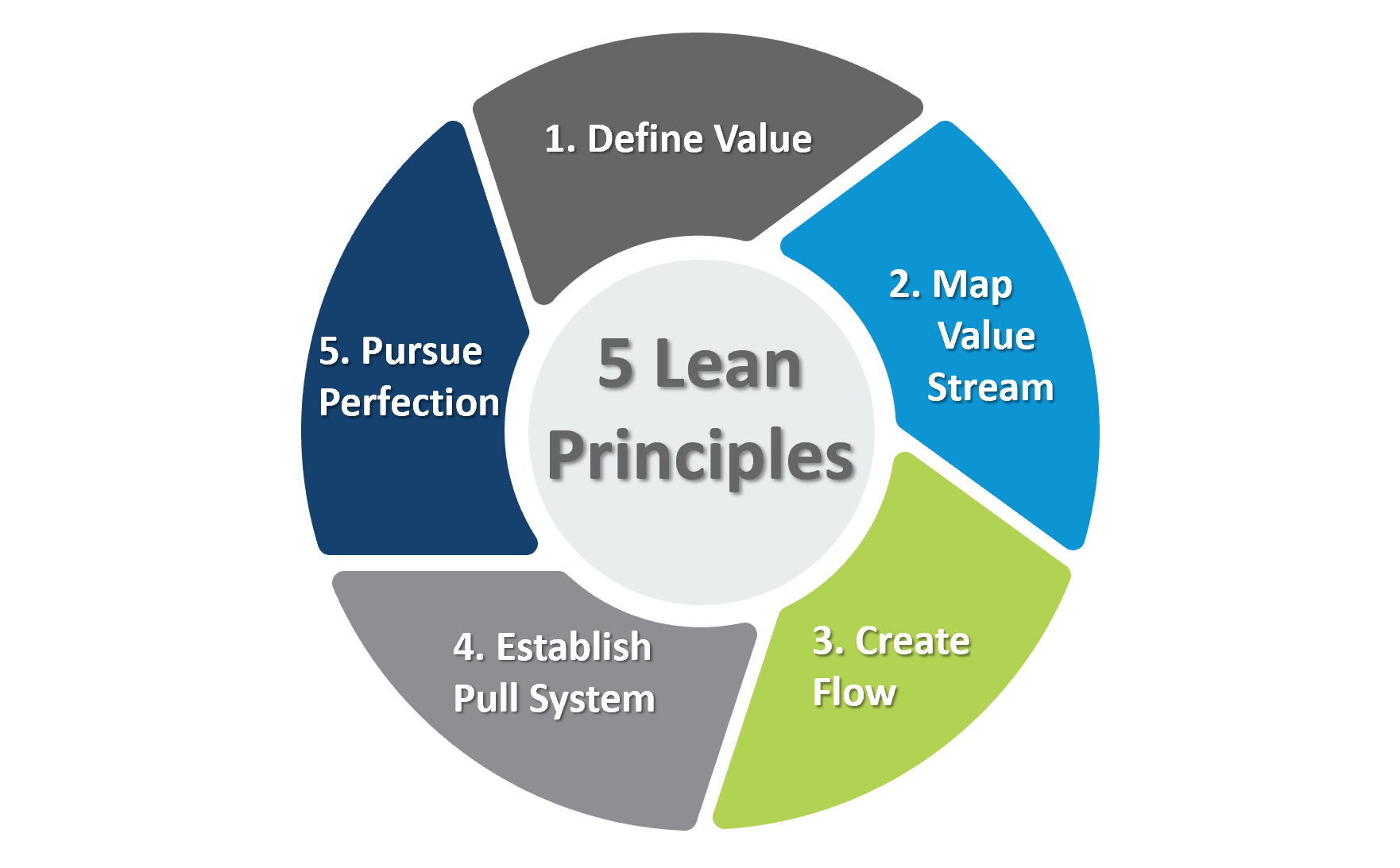

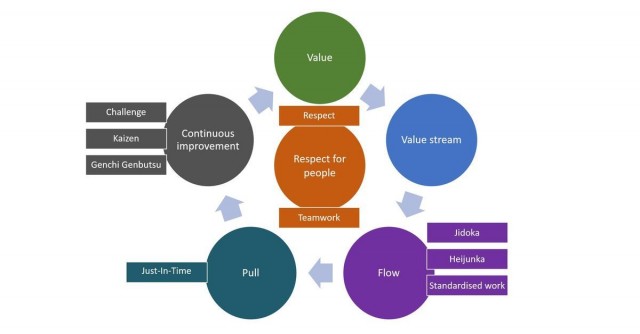

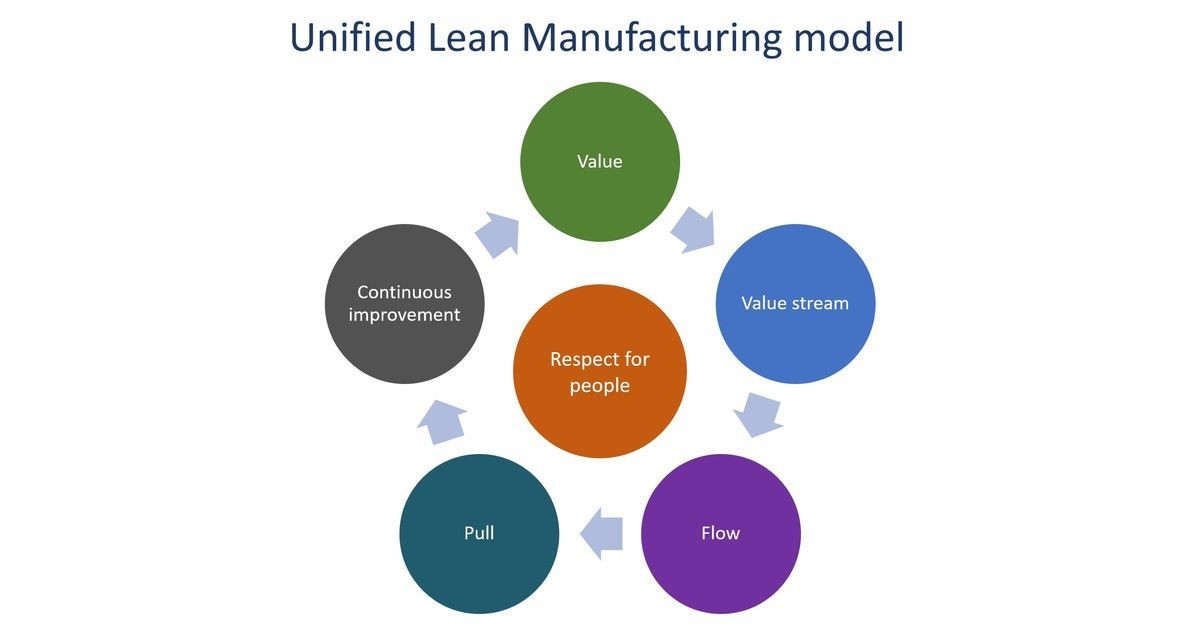

Five Principles Of Lean Manufacturing

Lean Manufacturing A Modernized Management Model

No comments for "Which of the Following Are Related to Lean Production"

Post a Comment